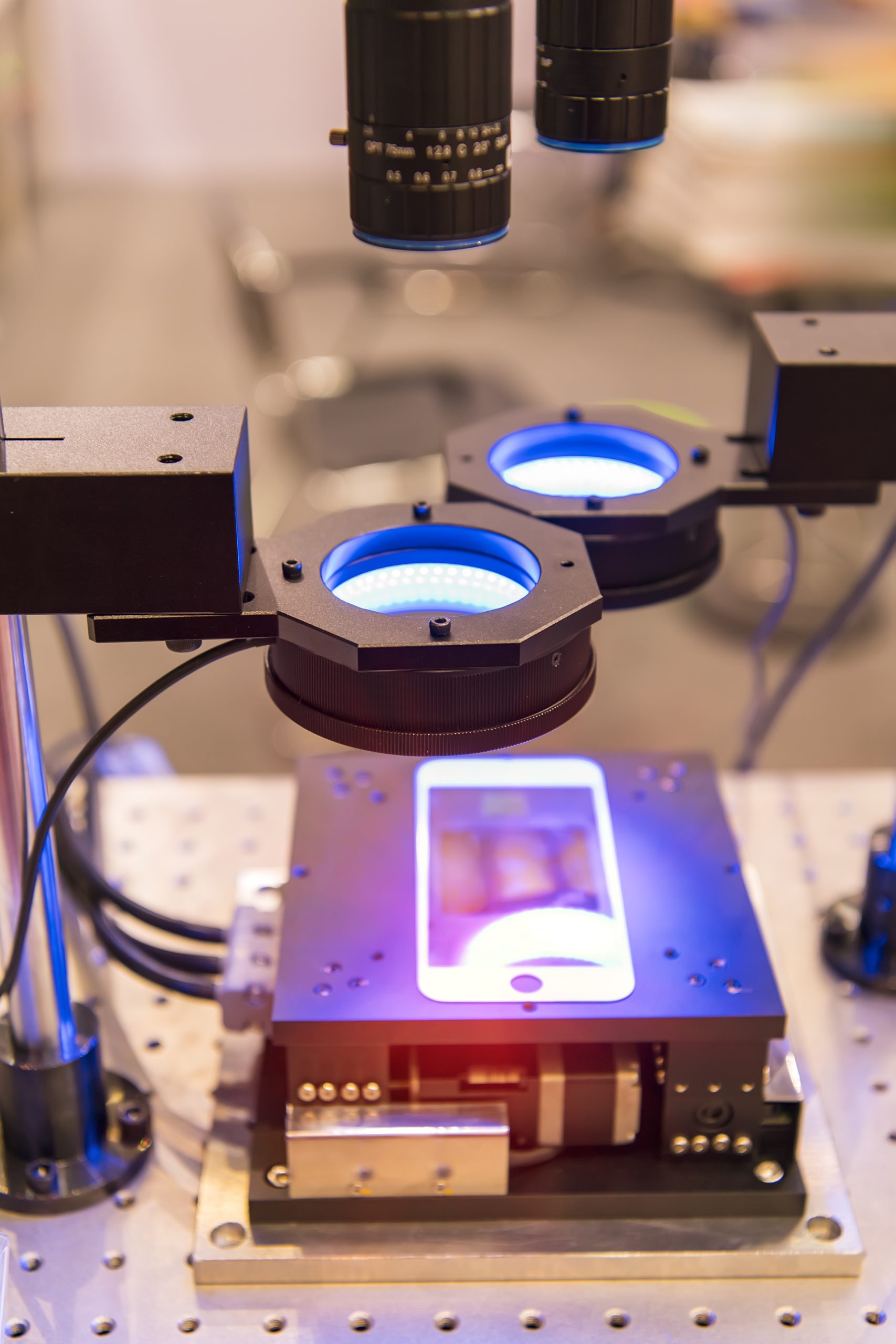

TURNKEY MACHINE VISION SOLUTIONS

Optimize production, improve decision making and the results of your company

Industrial machine vision systems are the set of tools and methods that allow images to be captured to process and analyze them. Thanks to this technology, it is possible to automate different types of processes, since the machines are provided with the information they need to make correct decisions during the performance of the tasks assigned to them.

Automation, thanks to computer vision, translates into better production results, more agile production phases and greater efficiency of quality controls.

These are the benefits of industrial machine vision for companies like yours

-

AProductivity increase

By applying quality controls to production processes, we remove faulty units before reaching the end of the line. This way, the final useful production increases significantly

-

Better use of materials

The elimination of units in poor condition throughout the entire production process means that the materials used in them are reserved for units that are in good condition.

-

Cost reduction

By making better use of available resources and reducing material loss, total production costs are considerably reduced

-

Better quality of the final product

It not only improves the production, but also the final product. This is a benefit for your customers since you will retain them, offering them a higher quality product

MACHINE VISION SOLUTIONS

-

DEFECT DETECTION

Detection of scratches, pitting, stains, lack of material and other defects.

-

ELEMENT CLASSIFICATION

Identification and classification by shapes, colors, sizes, etc.

-

2D/3D DIMENSIONAL CONTROL

Measurement of any type of solid element.

-

CODE READING

1D and 2D code reading.

-

PRODUCT COUNTING

Production volume quantification.

-

CHECK

Product status verification.

-

POSITIONING

Detection of the position of the part in X, Y and Z.

-

RECOGNITION

Reading of any type of source on different surfaces.