REVERSE ENGINEERING

Reverse engineering to obtain technical information

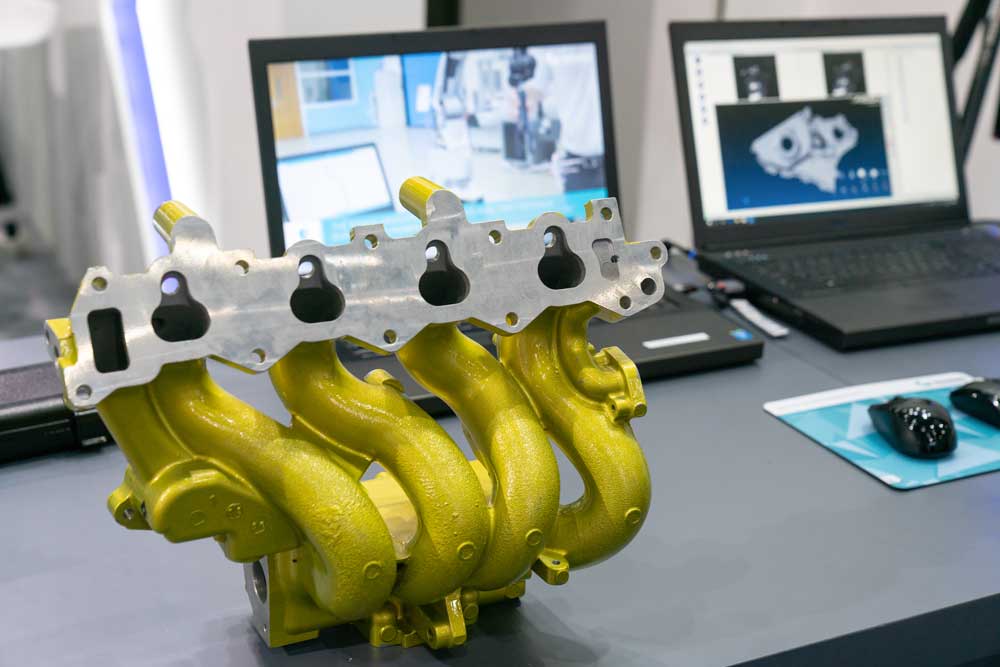

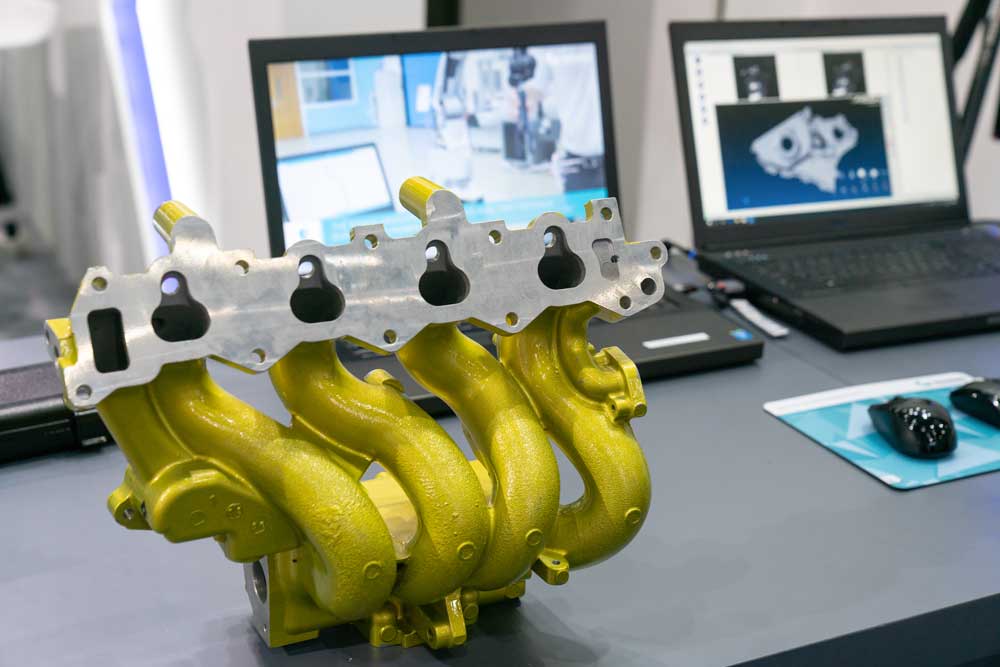

Reverse engineering of parts follows the opposite process to traditional engineering: we make a drawing starting from a part that already exists. Reverse engineering is useful to obtain the information necessary for the manufacture of real objects whose technical characteristics we do not know.

We start from a digital model created with the technique of 3D scanning or digitization. This 3D CAD model does not have the characteristics of actual dimensions, geometry and functionality, so we must validate it before using it to manufacture the product.

Validation is both dimensional and operational, and depends on the application. The final 3D CAD model format can be STL, PLY, STEP, IGES, etc.

What applications does reverse engineering have?

-

Optimization of manufacturing processes in surface recovery

-

Repair of data obtained by 3D scanning and reconstruction of parts

-

Modification of the design of existing objects

-

Data preparation for digital simulations and virtual manufacturing

-

Obtaining virtual part files